Dry Ice Cleaning IS ECO FRIENDLY

Swiss Technology Brought To The Gulf - Renowned Service - HACCP Compliant - Hundreds Of Loyal Customers -

Safer

Cost Effective

Faster

Eco-Friendly

Residue-Free

SAFER

CO2 Dry Ice cleaning is safe, non-toxic, non-flammable non-conductive, and approved for industrial use by the Department of Agriculture, the FDA and the Environmental Protection Agency. CO2 Dry Ice cleaning is a safe and environmentally responsible cleaning method during major outages or general maintenance schedules.

COST EFFECTIVE

Labour costs, workers' compensation, and environmental requirements are only a few examples of the burden many equipment operators experience in cleaning machines. Carbonic International brings new technology to the Middle East that alleviates these problems.

faster

You can dry ice cleaning straight onto an electric panel/motor, or engine and running machinery; even greasy kitchens and printing presses can be cleaned in a flash. Best of all there is no mess or water to clean up.

ECO-FRIENDLY

The disposal of cleaning residues like grit (sand), glass or plastic beads, water or crushed walnut shells is becoming impossible due to strict landfill disposal requirements and hazardous waste controls.

RESIDUE-FREE

Think about the removal of lead based paint from a one square foot area; this may require as much as ten pounds of sand to remove as little as two ounces of paint. This results in over ten pounds of lead contaminated waste requiring controlled disposal. CO2 pellets as the cleaning media eliminates waste disposal problems because it uses Zero Residue Technology (ZRT).

APPLICATION

Carbonic International's method is non-abrasive, eco-friendly, has no contamination or health risk problems and waste disposal of toxic substances is non-existant. more

technology

Carbonic International's solid CO2 pellets at -78째C are propelled through a high pressure self contained unit to clean the contaminated surface. more

solutions

Carbonic International FZCO's Dry Ice Cleaning can be used to remove oil, paint grease, asphalt, tar, decals, dirt, ink, resins, and adhesives to name a few. more

Dry Ice Cleaning FROM THE PIONEERS IN THE REGION

Application Technology + Infrastructure + 24 Hour Customer Service = Satisfaction Guaranteed

Place your trusted jobs in the most experienced hands in the region - call us now!

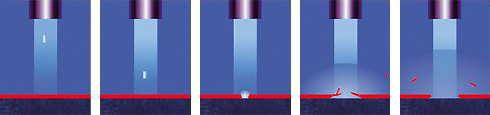

four stages of dry ice cleaning

- Tiny dry ice pellets at -78째C are propelled from a compact, self contained unit at supersonic speed through a dry ice cleaning gun using specially treated compressed air.

- The dry ice pellets hit the surface (to be removed or cleaned) creating a thermal shock wave.

- Upon impact they sublimate into gas breaking the surface-substrate bond.

- The resulting tension dislodges the surface material without damaging the substrate while the harmless CO2 gas from the sublimated dry ice is absorbed back into the atmosphere. There is no water, sand, grit, chemicals, solvents or other toxic secondary contaminants to discard with this eco-friendly technology.

Dry Ice Cleaning - Applications

This cleaning technology is non-abrasive, eco-friendly, has no contamination or health risk problems and waste disposal of toxic substances is non-existant

AIRFORCE

Removal of coating from airplanes, rockets, munitions etc. Rocket solid fuel and explosives washout and reconditioning.

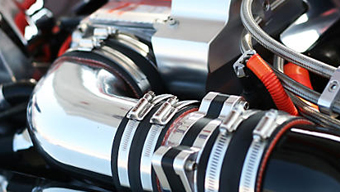

AUTOMOTIVE

Removal of paint and solder from booths, machinery, grating and conveyors. Engine and tools cleaning.

AVIATION

Engine cleaning, removal of grease, hydraulic fluid and rubber cleanup from runways and parking areas.

chemical plants

In-line cleaning of chemical deposits from boiler tubes, tanks, valves, evaporators, heat exchangers, pipes, vessels and chemical reactors.

construction

Exposing aggregate and rebar's, hydro demolishing, asphalt distributors, mixers, tar cookers and other machinery cleanup from tar and concrete.

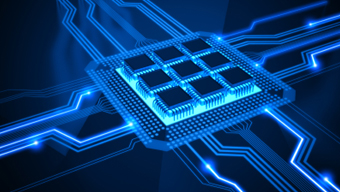

electronics

Surface preparation and cleaning of plasma displays, glass, ceramic and other matrices for electronic industries.

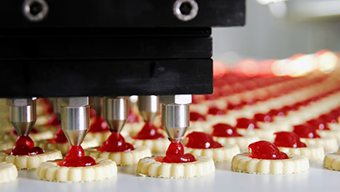

food processing

Dirt, Grease, oil, fats, dough, food residues from vats, ovens, mixers, conveyors and kitchen equipment.

FOUNDRIES

Removal of deposits, metal oxidation, ceramic and sand core materials for casting, furnaces and paddles.

POWER PLANTS

Nuclear decontamination of fuel capsules, "U" tube exchangers, flash from preheated tubes. Quick cleaning of hand tools and online cleaning of electrical equipment for Power Stations.

oil field

Paraffin and crude residues on platforms and storage tanks. Removal of drilling mud and cement from drilling pipes. Surface preparation for repainting.

PHARMACEUTICAL

Cleaning of chemicals (liquid and solids) from pipe, kettles, mixers, tubes, heat exchangers, reactors, filters and evaporators in pharmaceutical industry.

PIPE INDUSTRY

Removal of rust and varnish from industrial pipes prior to recoating, dope and oil from pipe threads for inspection, drilling mud and debris in various kind of pipe (internal and external cleaning).

PUBLIC UTILITIES

Reactors and insulators in public utilities, boiler tubes, vehicles and machinery. Water treatment plants and potable water reservoirs.

PULP AND PAPER

Paper plants: cleaning of grease, oil, pitch dirt and wood pulp from heat exchangers, tubes, foundries, press sections, screens and rollers of paper machines, suction rolls, stock chests and lines, black liquor.

REFINERIES

Wax, paraffin, grease and crude residues. Water scale, coke, hard carbons and polymers in heat exchangers, pipe, tubes and tanks.